When I discovered and was entranced by Metallica, frontman and rhythm guitar maestro James Hetfield was crunching away on a fairly beaten up Flying V, which he recently restored, by the way. So, then came “Master of Puppets” and James’ pristine, white Explorers. Over the years, these have evolved and he’s used white, black, wood grain, metal and gone from Gibson to ESP and, finally, to his signature model ‘Snakebyte.’ Well, I do tend to live in the past, especially musically, and my love for this guitar was no different. What I didn’t really want to do was spend a bazillion dollars on some signature model, nor close to a bazillion on one of the new-ish Explorers. So…I found a compromise. I ordered a DIY Explorer kit from BargainMusician.com. Here’s the kicker – they don’t have the kit, anymore! So, if you should be looking for an Explorer kit, I’d check out PitBullGuitars. Really, really.

At any rate, for $141, it came with everything you’d need to get an Explorer up and jamming. It just needed to be painted, finished, put together and named. Well, I guess you don’t need to name it, but mine came pre-named: “Li’l Het.” This was because of a nickname I was given in high school. I’ve since decided that sounded weird, so it’s just “The Het.”

I’ve never really had much confidence when doing projects on my guitars (as demonstrated by the 1.5 year pickup replacement project…), let alone putting together a kit and making a working guitar. So, when this kit arrived, I was immediately overwhelmed with the monumental task that lay ahead. I’m really not about the long game, and this was going to be a long game. That said, I’ve learned a LOT putting this together. So…this will chronicle this journey – the good, the bad and the definitely ugly.

Sanding is something that I’ve always been pretty decent at doing, all the way back to wood shop in the 8th grade when my balsa CO2 racer took second (or was it third? It was 30 years ago, so it’s blurry) in a city-wide competition. At any rate, I enjoy sanding. I enjoy taking an unfinished product and getting it “smoov.” The things, here, that require sanding are the body and neck.

Here we have the neck and body primed and partially sanded. What you can see in the first photo and in more detail, below, was a fairly large irritation. So, I had it resting, comfortably, and drying on a box configuration I’d been using for the past three weeks without issue. I prime and then I head out to do something else, closing the garage door behind me. Upon my return, as the garage door is going up, it was obvious that something was wrong because those parts that were expected to be in a certain place, weren’t. Instead, the neck and body were piled over the push mower. There was minimal damage on the neck, but a significant

Here we have the neck and body primed and partially sanded. What you can see in the first photo and in more detail, below, was a fairly large irritation. So, I had it resting, comfortably, and drying on a box configuration I’d been using for the past three weeks without issue. I prime and then I head out to do something else, closing the garage door behind me. Upon my return, as the garage door is going up, it was obvious that something was wrong because those parts that were expected to be in a certain place, weren’t. Instead, the neck and body were piled over the push mower. There was minimal damage on the neck, but a significant  divot on the Explorer’s body.

divot on the Explorer’s body.

I’ll be the first to admit that my woodworking skill is suspect at best and limited to sanding, really. That said, I went out and got some wood filler and set about making it less tragic. Spoiler – it’s not perfect, but there has been nothing about this project that was about perfection. As much as I wanted this to be the perfect replication of Het’s iconic Explorer(s), I knew that it wasn’t going to be, so I just set out to do the best I could in what would be considered a learning experience. It really, really reduces the stress when you allow yourself to make mistakes, which is good…

At any rate, one of things I was learning was that a good painting area was paramount and, in our garage, hard to come by. I finally settled on a tall cardboard box, bungee cords and a wire hanger. In conjunction, these came together for a usable area that I employed the rest of the way. So, I then set about painting. I started with the neck.

Painting was fun and went pretty painlessly. Well, except for when the temperature was a little lower than my non-updating weather app told me and I watched the paint on the back of the guitar literally become craquelure. Not cool. Well, actually – bottom line is don’t paint below 55 degrees F, and certainly not when it’s 42.

Painting was fun and went pretty painlessly. Well, except for when the temperature was a little lower than my non-updating weather app told me and I watched the paint on the back of the guitar literally become craquelure. Not cool. Well, actually – bottom line is don’t paint below 55 degrees F, and certainly not when it’s 42.

So, with the neck in good shape with several coats of paint, I should probably talk about the paint used. I used DupliColor Artic White and Bright White for the main colors. Priming was the 2-in-1 Filler Primer. It worked really well. Sanded down nicely. I was, however, overly concerned with the number of layers and sanding between applications. I really didn’t need to do that, from reading. Next time, I may try a different approach. So, I painted the neck, but wanted to wait until affixing the neck to the body before painting the body because I didn’t want to have to sand down a ton of excess paint to get the neck happy. It wasn’t a *bad* idea. I just, apparently, was a little tired when I glued the neck.

So, with the neck in good shape with several coats of paint, I should probably talk about the paint used. I used DupliColor Artic White and Bright White for the main colors. Priming was the 2-in-1 Filler Primer. It worked really well. Sanded down nicely. I was, however, overly concerned with the number of layers and sanding between applications. I really didn’t need to do that, from reading. Next time, I may try a different approach. So, I painted the neck, but wanted to wait until affixing the neck to the body before painting the body because I didn’t want to have to sand down a ton of excess paint to get the neck happy. It wasn’t a *bad* idea. I just, apparently, was a little tired when I glued the neck.

I used a happy clamp to press together that nice neck and body with Titebond Ultimate III waterproof glue. Best and worst decision ever. First, best – the neck isn’t going anywhere. Worst? Well, yeah…Apparently, when I set the neck in, I managed to go past the line I had drawn in with pencil, so it was just under a 1/4” too far forward into the neck pickup cavity. This wouldn’t be so bad, but I didn’t notice until a bit later…enough later that it didn’t matter. It wasn’t going anywhere.

I used a happy clamp to press together that nice neck and body with Titebond Ultimate III waterproof glue. Best and worst decision ever. First, best – the neck isn’t going anywhere. Worst? Well, yeah…Apparently, when I set the neck in, I managed to go past the line I had drawn in with pencil, so it was just under a 1/4” too far forward into the neck pickup cavity. This wouldn’t be so bad, but I didn’t notice until a bit later…enough later that it didn’t matter. It wasn’t going anywhere.

As a side note, I used the aforementioned Titebond to repair an acoustic guitar bridge and it seems to be as solid as anything one could ask for.

So, it came time to paint the whole she-bang. I learned a lot of what not to do during this time frame. The first was that when I masked off the neck the first time, I used standard blue masking tape and lots of it. That led to missteps, el grande. The main thing that happened was that the lesser tape grade (more on that in a minute) allowed a bit more seepage than I wanted or expected. Then, I was a giant idiot and tried to sand the paint and tape residue off the fretboard. Note to self and to those of you who would be tempted by this path: Coconut Oil and elbow grease will do the job and not leave your fretboard look like it was partially inserted into a garbage disposal. I’m kind of embarrassed by it, but it is what is, at this point, so we move on! This next time, I masked off the neck with Blue Platinum (I highly recommend this tape), this time, and it was a much more satisfactory experience.

So, it came time to paint the whole she-bang. I learned a lot of what not to do during this time frame. The first was that when I masked off the neck the first time, I used standard blue masking tape and lots of it. That led to missteps, el grande. The main thing that happened was that the lesser tape grade (more on that in a minute) allowed a bit more seepage than I wanted or expected. Then, I was a giant idiot and tried to sand the paint and tape residue off the fretboard. Note to self and to those of you who would be tempted by this path: Coconut Oil and elbow grease will do the job and not leave your fretboard look like it was partially inserted into a garbage disposal. I’m kind of embarrassed by it, but it is what is, at this point, so we move on! This next time, I masked off the neck with Blue Platinum (I highly recommend this tape), this time, and it was a much more satisfactory experience.

So, I got the body and neck painted and sanded. It looked pretty tight, at this point, except for the neck carnage – as evidenced by the next couple of photos – and I was ready to start putting the beast together. Well, OK – start getting all the pieces together and making sure they are ready to go when I am. That went mostly painlessly.

So, I got the body and neck painted and sanded. It looked pretty tight, at this point, except for the neck carnage – as evidenced by the next couple of photos – and I was ready to start putting the beast together. Well, OK – start getting all the pieces together and making sure they are ready to go when I am. That went mostly painlessly.

So, here you can see the butchery on the fretboard. Man…deep regrets, here. But, everything else was looking good. I put things in their places – pots, switch, pickups, and just about everything was as it should be. What wasn’t? Well, that would be the neck pickup. If you recall, I didn’t notice that the neck was 1/4” (or less) too far forward into the neck pickup cavity. How did I figure this out? With a demonstration, of course, when I tried to fit the neck pickup into it’s nice cozy home…and it didn’t fit. So, I did what any ra

So, here you can see the butchery on the fretboard. Man…deep regrets, here. But, everything else was looking good. I put things in their places – pots, switch, pickups, and just about everything was as it should be. What wasn’t? Well, that would be the neck pickup. If you recall, I didn’t notice that the neck was 1/4” (or less) too far forward into the neck pickup cavity. How did I figure this out? With a demonstration, of course, when I tried to fit the neck pickup into it’s nice cozy home…and it didn’t fit. So, I did what any ra nk amateur would do, and that was to break out a file and start contouring the pickup cavity to accommodate the pickup which was mainly too wide based on where it would end up because it was a bit forward. So…the corners. This is why we love humbucker pickup rings. They dutifully covered the carnage when everything was said and done.

nk amateur would do, and that was to break out a file and start contouring the pickup cavity to accommodate the pickup which was mainly too wide based on where it would end up because it was a bit forward. So…the corners. This is why we love humbucker pickup rings. They dutifully covered the carnage when everything was said and done.

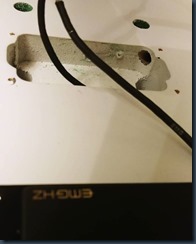

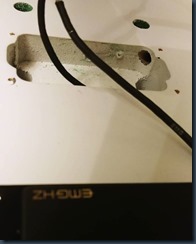

A note on pickup rings and EMGs – make sure they’re similar. I say this because the rings I had came from the humbuckers that shipped with the kit. I have not idea if they’re solid or not, as to fit the Het aesthetic, they needed to be EMGs, and sonically, they needed to be the 81/60 set or, in this case, the passive equivalent, hence the Hz H4/H4A  combination. So, the pickups and rings were from different eras, it would seem, and the screws from the EMGs were decent enough for the rings, but man, I had to dig around for springs because the ones that came with the humbuckers were a bit on the long side and, as you can see from the photo, look like they would be perfectly poised to launch the screw at several hundred feet per second. So, I adjusted slightly and then both pickups were in their rings, waiting for installation. One slight problem, though – with the neck so far forward, the neck pickup was literally touching the neck, meaning the ring was going to need a little modification in order to be used. More on that, later.

combination. So, the pickups and rings were from different eras, it would seem, and the screws from the EMGs were decent enough for the rings, but man, I had to dig around for springs because the ones that came with the humbuckers were a bit on the long side and, as you can see from the photo, look like they would be perfectly poised to launch the screw at several hundred feet per second. So, I adjusted slightly and then both pickups were in their rings, waiting for installation. One slight problem, though – with the neck so far forward, the neck pickup was literally touching the neck, meaning the ring was going to need a little modification in order to be used. More on that, later.

This is pretty much just a picture of the pickup cavities for the sole reason that those little holes, there, are supposed to take *both* sets of pickup wires to the  electronics cavity. I suppose that if you were using the stock pickups, the hole would probably be the correct size. As it stands, both sets of 4-wire connector for the EMGs was a bit of a train wreck. I’m honestly surprised they work. Basically, even after enlarging the hole a bit, they still weren’t going to fit. So, I had to, basically, sever and splice which, as we all know in guitar circles, isn’t necessarily optimal. It was, however, how things would have to be since there was no way that both sets of wires plus each connector end was going to fit through the hole provided. It’s a good thing I’ve gotten comfortable with soldering, again. I don’t think I’ll go the “quick connect” route, again, with passives. It’s just not that much easier, really, than just soldering. I’ll address the connections, later on, in the wiring section.

electronics cavity. I suppose that if you were using the stock pickups, the hole would probably be the correct size. As it stands, both sets of 4-wire connector for the EMGs was a bit of a train wreck. I’m honestly surprised they work. Basically, even after enlarging the hole a bit, they still weren’t going to fit. So, I had to, basically, sever and splice which, as we all know in guitar circles, isn’t necessarily optimal. It was, however, how things would have to be since there was no way that both sets of wires plus each connector end was going to fit through the hole provided. It’s a good thing I’ve gotten comfortable with soldering, again. I don’t think I’ll go the “quick connect” route, again, with passives. It’s just not that much easier, really, than just soldering. I’ll address the connections, later on, in the wiring section.

OK – so, back out to the garage/workshop (mainly garage…) to do some final things. Now that the paint has had time to set – but not enough, because I’m a  rookie and impatient. So, masking the neck, again, I use DupliColor clearcoat. I apply a coat at a time, 5+ times (I don’t remember…it was sometime after midnight by the time I finished.) and then bring it inside to cure, as it was supposed to get down into the 40s, that night which, as we’ve learned, creates undesirable results. Unless weird crackling everywhere is what you were going for, in which case, that’s a pretty easy way to get that look.

rookie and impatient. So, masking the neck, again, I use DupliColor clearcoat. I apply a coat at a time, 5+ times (I don’t remember…it was sometime after midnight by the time I finished.) and then bring it inside to cure, as it was supposed to get down into the 40s, that night which, as we’ve learned, creates undesirable results. Unless weird crackling everywhere is what you were going for, in which case, that’s a pretty easy way to get that look.

My attention span and enthusiasm tag teamed to get this thing back out into the garage on a warm-ish day to put some of the final touches onto The Het. First, I  mask off parts of the body and the sides of the neck – I’m going to try to do something about my abuse of the fretboard. I got a nice ebony stain. I figured at the very least it would help darken up the spots that I sanded the hell out of and, at best, would make it look ebony-er. You heard me. It actually worked pretty well. The main side effect that could be considered “bad” would be that the inlay dots all but disappeared. That said, I like the look. Ah, but you’re wondering “what’s that green stuff?!” Good question. Once the stain had set, I used turtle wax and “swirl eliminator,” for what that’s worth. The good? It gave it a nice shine, without over-glossing, which is what I was looking for. The bad? I still have green in some of the hard to reach areas.

mask off parts of the body and the sides of the neck – I’m going to try to do something about my abuse of the fretboard. I got a nice ebony stain. I figured at the very least it would help darken up the spots that I sanded the hell out of and, at best, would make it look ebony-er. You heard me. It actually worked pretty well. The main side effect that could be considered “bad” would be that the inlay dots all but disappeared. That said, I like the look. Ah, but you’re wondering “what’s that green stuff?!” Good question. Once the stain had set, I used turtle wax and “swirl eliminator,” for what that’s worth. The good? It gave it a nice shine, without over-glossing, which is what I was looking for. The bad? I still have green in some of the hard to reach areas.

Additionally, while I was in the workshop/garage, I decided to do something about  the truss rod cover. I know that on Hetfield’s Explorers, a) the headstock is black and b) so is the truss rod cover. Guess what? You’re not the boss of me. I wanted the white headstock in case I felt the need to scribble a logo on it or something. I didn’t, but what I did want was just a little personality up there, so I took the black truss rod cover and did a marbling effect using the white paint and the red paint I was originally going to use for the Red Wings logo on the main body horn. Since I went for the pure white Het look, I had some red paint I felt needed some love. So, I used the rag I used to polish the body, applied red paint, dabbed at it a bit, applied white paint and dabbed it as well. What came out was a sort of weird red marble looking thing which I kind of dug, so I left it that way.

the truss rod cover. I know that on Hetfield’s Explorers, a) the headstock is black and b) so is the truss rod cover. Guess what? You’re not the boss of me. I wanted the white headstock in case I felt the need to scribble a logo on it or something. I didn’t, but what I did want was just a little personality up there, so I took the black truss rod cover and did a marbling effect using the white paint and the red paint I was originally going to use for the Red Wings logo on the main body horn. Since I went for the pure white Het look, I had some red paint I felt needed some love. So, I used the rag I used to polish the body, applied red paint, dabbed at it a bit, applied white paint and dabbed it as well. What came out was a sort of weird red marble looking thing which I kind of dug, so I left it that way.

On to the electronics. This is where all sort of weird things had to happen. The first thing that was a) regrettable and b) kind of unavoidable, at that point, was that the neck pickup was going to need to be rammed in there to get it into the hole.  So, I put the wiring through the miniscule hole and into the next pickup cavity.

So, I put the wiring through the miniscule hole and into the next pickup cavity.

Attaching the easy-connector thing, I set the H4A in and pushed to get it as far as I could, manually. It was then necessary to put a nice cloth over top, folded a number of times to reduce what was coming next, and then hammer it into place. Yeah…physically beating a $70 pickup with a hammer. On one hand, it’s never coming out…ever… and, thankfully, was able to be put in to a level where it’s not interfering with string clearance or anything like that. That’s good, because, like I said, it’s not going anywhere anytime soon. So, that brought on the second painful modification. I measured and measured again and then clipped the pickup ring in the requisite spots so it hugged the neck, nicely, and looked like it was meant to do that. I then drilled the holes and affixed the pickup ring for the neck pickup. Thankfully, the bridge pickup was a lot easier, the only real challenge was when I realized there was just no way that the 4-wire bundles and connectors were going to fit, so something had to be done.

I then cut and stripped those beautiful 4-wire, shielded, bundles, separating out the leads and soldering other wires to it that would, indeed, fit through the wire hole. This felt like sacrilege, but it worked. Well, OK, it mostly worked. Like I mentioned, the neck pickup may have had some issues and, at this point, it doesn’t work. I’m not going to stress about it too much, at this point, as I really mainly do rhythm chugging, anyway, but, at some point I’ll need to figure out if it’s the wiring to the switch or actually the pickup wiring. One has a much greater chance of being able to be fixed.

I then cut and stripped those beautiful 4-wire, shielded, bundles, separating out the leads and soldering other wires to it that would, indeed, fit through the wire hole. This felt like sacrilege, but it worked. Well, OK, it mostly worked. Like I mentioned, the neck pickup may have had some issues and, at this point, it doesn’t work. I’m not going to stress about it too much, at this point, as I really mainly do rhythm chugging, anyway, but, at some point I’ll need to figure out if it’s the wiring to the switch or actually the pickup wiring. One has a much greater chance of being able to be fixed.

I mentioned the connections and the “easy connectors.” Yeah, that didn’t all work out the way I think anyone intended. First and foremost, the Explorer electronics cavity was not made for such things and so the main connector patch section thing is stuffed in just on top of the volume pot. The other challenge was that the screw down terminals for the grounds and switch connectors were…iffy with thinner wires. Even screwing down the terminal screw as far as it would go, the wires would pull out almost immediately. This, to me, was irksome, so, I soldered the wires to their terminals. Now you see why I am just thinking it’s easier to just solder everything from the get-go. I will say that the spade connectors for the jack were very helpful, but also were soldered – they just held on, themselves, when soldering.

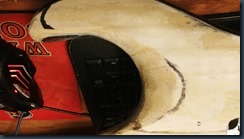

And so, it became time to see if this thing worked, from an actual playable instrument point of view. To the right is a picture of the  whole assembly and you can see the neck is a bit darker than standard rosewood and there’s really only one inlay dot visible. I think it looks pretty good. It’s not perfect, but I never expected it to be. I know – why did I do it if I didn’t expect it to be perfect? Because I wanted to get a feel for what would be involved taking a kit – I think we can all agree I’m not ready to take a plank of wood – from bare wood to assembled, playable guitar. I did that. I have a much better understanding of what is involved from a primer/filler/sanding/painting standpoint. It’s a pain, sometimes, but that’s mostly because I don’t really have a proper place to do this kind of thing nor do we have a consistent enough temperature around the time I started this to get decent work done without a lot of errors. I’ve also learned that there are some *ahem* Chinese outlets that have some of the hardware and luthier equipment for pennies on the dollar and that I can cut down on some costs, that way, while still keeping the final product looking and sounding good.

whole assembly and you can see the neck is a bit darker than standard rosewood and there’s really only one inlay dot visible. I think it looks pretty good. It’s not perfect, but I never expected it to be. I know – why did I do it if I didn’t expect it to be perfect? Because I wanted to get a feel for what would be involved taking a kit – I think we can all agree I’m not ready to take a plank of wood – from bare wood to assembled, playable guitar. I did that. I have a much better understanding of what is involved from a primer/filler/sanding/painting standpoint. It’s a pain, sometimes, but that’s mostly because I don’t really have a proper place to do this kind of thing nor do we have a consistent enough temperature around the time I started this to get decent work done without a lot of errors. I’ve also learned that there are some *ahem* Chinese outlets that have some of the hardware and luthier equipment for pennies on the dollar and that I can cut down on some costs, that way, while still keeping the final product looking and sounding good.

All in all, this was an amazing experience, and it didn’t take long to get hooked. I’m a little twitchy, now, since it’s coming onto winter which, as we found out earlier, is not a good time to paint anything. Ah, well. Could be worse. It’s not like I’ve got another project waiting in the wings…or do I?

is, now. I know that’s a crude way to put it, but I’m not sure of all the terminology. You can see that the approach, or maybe, transition to the neck pocket, still needs a bit of rounding and smoothing. Part of that is the angle from which the picture was taken and part of it is that it does, really, need a bit more love. Thankfully, though, it’s not a lot of work left, there. The cutaway contour is coming along nicely and this is where the “not knowing what I’m looking for but knowing it when I see it” comes into play.

is, now. I know that’s a crude way to put it, but I’m not sure of all the terminology. You can see that the approach, or maybe, transition to the neck pocket, still needs a bit of rounding and smoothing. Part of that is the angle from which the picture was taken and part of it is that it does, really, need a bit more love. Thankfully, though, it’s not a lot of work left, there. The cutaway contour is coming along nicely and this is where the “not knowing what I’m looking for but knowing it when I see it” comes into play.